Introduction

The textile industry stands at a pivotal moment in 2026, where sustainability is no longer optional—it’s the new baseline. With the sustainable fabrics market projected to reach USD 41.28 billion this year and expected to surge to USD 115.72 billion by 2035 at a 12% CAGR, fashion brands must adapt or risk obsolescence. This comprehensive guide explores the five transformative sustainable fabric trends defining 2026, backed by market data and expert insights to help your brand navigate this eco-conscious revolution.

1. Bio-Based and Regenerated Fibers: The New Industry Standard

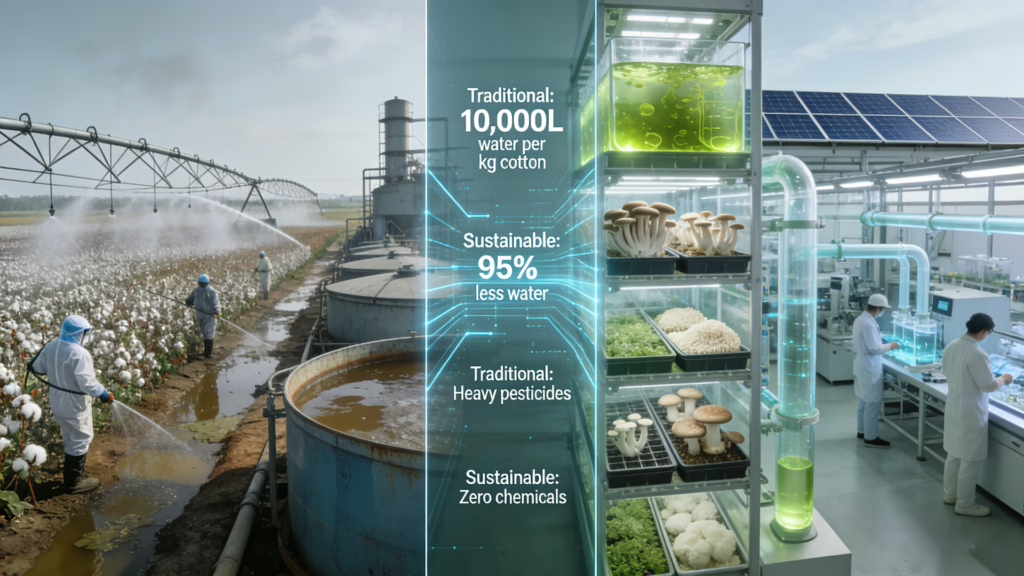

From Niche to Mainstream

Bio-based textiles have transcended their status as niche alternatives to become the industry standard in 2026. Materials like Tencel (lyocell), Seacell, and innovative fibers derived from algae, mushrooms, and agricultural waste are revolutionizing fabric production.

Key Materials Leading the Charge:

Lyocell/Tencel: Made from sustainably sourced wood pulp through a closed-loop process that recycles 99% of water and solvents, lyocell offers superior moisture management, natural freshness, and luxurious softness that improves with washing. Its versatility makes it ideal for both casual wear and performance sportswear.

Mushroom Mycelium Leather: Companies like MycoWorks and Hydefy cultivate fungi into leather-like sheets that mimic animal hide at dramatically lower environmental costs. The manufacturing process is revolutionary—sheets can be grown to exact dimensions, eliminating cutting waste associated with traditional leather.

Algae-Based Fibers: Seacell and other algae-derived materials offer natural antibacterial properties while sequestering carbon during cultivation, creating a negative carbon footprint production process.

Agricultural Waste Innovations: Banana, pineapple (Piñatex), apple, and even coffee grounds are being transformed into functional textiles, giving new life to materials that would otherwise contribute to landfills.

Market Impact

According to ISPO Textrends jury member Louisa Smith, “Sustainability has become the standard. All products now have some form of sustainable ingredient or process—this is now a fundamental expectation, not a differentiator.”

2. Circular Economy and Recycled Textiles: Closing the Loop

The Recycling Revolution

The circular textile economy is accelerating with technological breakthroughs making fiber-to-fiber recycling commercially viable. The global recycled textile market is projected to grow at 3.6% CAGR through 2033, driven by both innovation and regulation.

Key Developments:

Advanced Recycling Technologies:

- Enzymatic Recycling: European startups Carbios and Samsara have developed enzymatic processes for “infinite” polyester recycling

- Chemical Recycling: Companies like Circ, Re:NewCell, and Syre (backed by H&M) are scaling chemical recycling methods that can break down blended fabrics

- Mechanical Recycling: High-speed textile sorting machines with AI-powered fiber identification are improving recycling efficiency

Post-Consumer Cotton Regeneration: White cotton waste recycling is now commercially viable, expanding beyond polyester-focused recycling programs.

Recycled Polyester (rPET): While currently representing less than 1% of total polyester production, rPET adoption is expanding rapidly as brands commit to circularity targets. Made from plastic bottles and textile production scraps, rPET reduces oil dependency and plastic pollution.

Regulatory Drivers

The EU’s Extended Producer Responsibility schemes and Digital Product Passports are mandating greater transparency and recyclability, with bans on destroying unsold stock (historically 21% of output). WRAP reports indicate that repair services now displace 82.2% of new garment purchases, pushing manufacturers to enhance fiber strength and durability.

3. Smart and Performance Textiles: Fashion Meets Function

Technology-Integrated Fabrics

Smart textiles are transitioning from concept to commercial reality in 2026, integrating sensors, conductive yarns, and responsive coatings that collect real-time data and adapt to environmental conditions.

Applications Driving Growth:

Health and Wellness Monitoring:

- Fabrics that track heart rate, body temperature, hydration levels, and movement patterns

- Medical textiles (projected to grow fastest at 25% market share) using sustainable materials for healthcare applications

Adaptive Performance:

- Thermochromic Fabrics: Color-changing textiles responding to temperature

- Thermal-Adaptive Materials: Automatically adjusting breathability and insulation based on climate or body temperature

- Moisture-Wicking with Antibacterial Finishing: Extended wear without frequent washing, aligning with sustainability goals

Sustainable Smart Textiles: The newest innovations focus on recyclability, with bio-based circuits and sensors designed for end-of-life disassembly to avoid e-waste concerns.

Industry Adoption

Kutay Saritosun, Director at Bluesign, notes: “Innovation may have slowed in some areas, but smart textiles represent the next frontier for premium activewear. Early movers will shape consumer expectations for the next decade.”

4. Sustainability Certifications Evolution: GOTS, OEKO-TEX, and Beyond

Certification Landscape 2026

As greenwashing concerns intensify, third-party certifications have become crucial trust signals. Understanding these standards helps brands make informed sourcing decisions and communicate authenticity to consumers.

Primary Certifications:

GOTS (Global Organic Textile Standard)

- Scope: Comprehensive certification covering the entire supply chain from organic fiber cultivation to finished product

- Requirements:

- Minimum 70% organic fibers (GOTS “Made with Organic”)

- Minimum 95% organic fibers (GOTS “Organic”)

- Strict chemical restrictions (no formaldehyde, heavy metals, PFCs)

- Environmental management and wastewater treatment

- Social compliance with ILO standards (fair wages, no child labor)

- Ideal For: Organic cotton, hemp, wool products; brands prioritizing full supply chain transparency

OEKO-TEX Standard 100

- Scope: Product safety certification testing finished textiles for harmful substances

- Requirements:

- Tests for 100+ harmful chemicals (pesticides, heavy metals, formaldehyde, phthalates)

- Testing at all processing levels including accessories

- No fiber type restrictions (applies to synthetic, natural, and blends)

- Ideal For: Chemical safety assurance; suitable for all fiber types including polyester

- Note: Does NOT certify organic status or ethical production

OEKO-TEX STeP (Sustainable Textile Production)

- Scope: Production facility certification for environmental and social compliance

- Focus: Environmentally friendly processes, worker health/safety, socially responsible conditions

Emerging Certifications:

- Global Responsible Textile Standard (GRTS): Currently in development as GOTS Version 8.0

- Organic Content Standard (OCS): Verifies organic fiber content (5-95% OCS Blended; 95%+ OCS 100)

- GRS (Global Recycled Standard): Certifies recycled content and chain of custody

Certification Strategy

Braz Costa, General Manager of CITEVE, emphasizes: “Certification is expensive but essential. The license number verification on official websites provides consumers with verifiable proof. Brands without certification must demonstrate equivalent standards through transparent documentation.”

5. Natural Fiber Renaissance: Cotton, Hemp, and Linen Reimagined

Traditional Fibers with Modern Innovation

Natural fibers are experiencing renewed attention in 2026, but with critical sustainability improvements addressing historical environmental concerns.

Leading Natural Fibers:

Organic Cotton

- Improvements: Non-GMO, pesticide-free cultivation; reduced water consumption through regenerative agriculture

- Innovations: Blends with elastane for athleisure applications; combinations with recycled fibers for enhanced performance

- Market Position: Cotton segment projected to hold 40% market share by 2035

- Example: Botto Giuseppe’s American Wool Tec uses fiber from Shaniko farms in Oregon practicing Carbon Initiative regenerative agriculture

Hemp

- Benefits: Rapid growth, minimal water requirements, no pesticide needs, soil regeneration properties

- Applications: Casualwear, outdoor apparel, technical textiles

- Performance: Strong, breathable, naturally moisture-wicking

- Note: GOTS certification available for hemp when entire processing chain is compliant

Linen

- Sustainability: Low-impact cultivation; naturally biodegradable

- Properties: Exceptional breathability, strength, improves with washing

- Trend: Enhanced through special treatments and blends with other sustainable fibers

Quality and Durability Focus

GOTS certification includes quality controls ensuring longevity—a crucial sustainability factor. As noted by industry observers, “It defeats the purpose if organic garments are discarded after a few months due to poor quality.”

Market Forecast and Consumer Trends

By the Numbers

Global Market Projections:

- Sustainable fabrics market: USD 41.28 billion (2026) → USD 115.72 billion (2035)

- Overall textile market: USD 760.28 billion (2025) → USD 974.38 billion (2030)

- Sustainable textile materials: USD 7.4 billion (2024) → USD 16.5 billion (2033) at 9.6% CAGR

Regional Leadership:

- Asia-Pacific dominates with 36.9-52% market share (manufacturing base + rising consumer awareness)

- Europe: Sustainability regulation driver; strong premium segment growth

- North America: Fastest growth rate driven by consumer demand and corporate commitments

Application Breakdown:

- Clothing: 50%+ revenue share

- Medical textiles: 25% (fastest-growing application)

- Home furnishings: 15%

- Other applications: 10%

Consumer Behavior Shifts

According to market research:

- 58% of manufacturers now prioritize sustainable yarn

- 47% of global consumers demand eco-friendly textile materials

- 59% of French consumers admit confusion about textile labels despite their prevalence

- Online mentions of “eco-friendly” and “bio-based” materials have risen steadily post-pandemic

- Millennials and Gen Z lead sustainable purchasing behavior

Brand Strategy: How to Adapt to Sustainable Fabric Trends

1. Supply Chain Transparency and Traceability

Action Steps:

- Implement blockchain or digital tracking systems for fiber-to-finished-product traceability

- Obtain relevant certifications (GOTS, OEKO-TEX) with publicly verifiable license numbers

- Publish annual sustainability reports with specific metrics (water usage, carbon footprint, waste reduction)

- Map and audit entire supply chain including Tier 2 and Tier 3 suppliers

Technology Solutions: Digital Product Passports (required by EU regulations) provide consumers with comprehensive product lifecycle information via QR codes.

2. Material Innovation and R&D Investment

Strategies:

- Partner with textile innovation companies (Lenzing for Tencel, Carbios for enzymatic recycling)

- Allocate 5-10% of product development budget to sustainable material testing

- Establish pilot programs with bio-based material suppliers

- Create cross-functional teams combining designers, sustainability experts, and material scientists

Example: Stella McCartney, Adidas, and Patagonia invest heavily in natural fiber blends, demonstrating how bio-based textiles can reshape fashion while maintaining design integrity.

3. Circular Design Principles

Implementation:

- Design for disassembly: Use mono-materials or easily separable components

- Choose recyclable trims and accessories (GOTS extends to hangtags requiring recycled or FSC-certified paper)

- Establish take-back programs and partnerships with textile recyclers

- Integrate durability testing to extend product lifecycle

- Offer repair services (82.2% of consumers now prefer repair over new purchases)

4. Consumer Education and Authentic Communication

Communication Framework:

- Avoid greenwashing: Make specific, verifiable claims with certification backup

- Educate consumers on care practices that extend garment life

- Create transparent messaging explaining sustainability trade-offs and continuous improvement

- Use storytelling to connect consumers with fiber origins and production processes

Trust Signals:

- Display certification logos prominently with license numbers

- Provide QR codes linking to detailed sustainability data

- Share behind-the-scenes production content showing sustainable practices

5. Regulatory Compliance and Future-Proofing

Preparation for 2026+ Regulations:

- EU Ecodesign for Sustainable Products Regulation: Requires durability, recyclability, and recycled content minimums

- Extended Producer Responsibility (EPR): Plan for end-of-life product management costs

- Ban on Unsold Stock Destruction: Improve demand forecasting and production planning

- PFAS-Free Requirements: Transition to clean chemistry in coatings and membranes

Competitive Advantage: Brands meeting 2026 regulations now will avoid costly retrofitting and gain first-mover advantages.

6. Performance Without Compromise

Quality Standards:

- Balance sustainability with functional performance (moisture-wicking, durability, comfort)

- Invest in innovative blends combining sustainable fibers with necessary technical properties

- Maintain rigorous quality control ensuring sustainable products match or exceed conventional alternatives

Market Positioning: Position sustainable products as premium offerings with superior performance, not compromises.

Expert Insights: Industry Leaders Weigh In

Sophie Bramel, Technical Editor, World Sports Activewear (WSA)

“Innovation has slowed in some areas, but what we’re seeing is a maturation of sustainable technologies. The focus has shifted from novelty to scalability and commercial viability. Brands that can successfully bring bio-based and recycled materials to market at competitive prices will dominate the next decade.”

Giusy Bettoni, CEO and Founder, CLASS

“Sustainability is no longer a ‘nice-to-have’ marketing message—it’s a fundamental business requirement. Consumers, particularly younger demographics, will abandon brands that don’t demonstrate authentic commitment to environmental responsibility.”

Thomas Håkansson, Creative Director and Senior Designer

“The most exciting developments aren’t just in new materials, but in how we’re rethinking entire production systems. Circular design, where products are created with their end-of-life in mind, represents the future of responsible fashion.”

Challenges and Considerations

Cost Factors

Sustainable fabrics often carry higher upfront costs due to:

- Certification fees and audit expenses

- Smaller production runs during scaling phase

- Investment in new supply chain relationships

- R&D for material testing and integration

Mitigation: Strategic partnerships, government incentives (e.g., India’s USD 1.44 billion textile sector investment), and long-term cost savings through efficiency improvements.

Supply Chain Complexity

Challenges:

- Limited availability of certified sustainable materials at scale

- Geographic concentration of specialized suppliers

- Longer lead times for sustainable material sourcing

- Need for supplier education and capability building

Solutions: Early supplier engagement, multi-sourcing strategies, and collaborative industry initiatives.

Performance Trade-offs

Some sustainable materials may initially underperform in specific technical applications. Continuous innovation is addressing these gaps through:

- Advanced fiber blending techniques

- Improved finishing treatments

- Enhanced material processing technologies

Conclusion: The Sustainable Imperative

The textile industry’s transformation in 2026 is undeniable: sustainability has evolved from optional differentiation to mandatory baseline. Fashion brands face a clear choice—adapt proactively to sustainable fabric trends or struggle with regulatory compliance, supply chain disruption, and consumer backlash.

The five trends outlined—bio-based fibers, circular economy practices, smart textiles, certification evolution, and natural fiber innovation—represent interconnected pathways to a more sustainable future. Success requires integrated strategies combining material innovation, supply chain transparency, circular design principles, authentic communication, regulatory compliance, and uncompromised performance.

The opportunity is substantial: The sustainable fabrics market’s projected growth to USD 115.72 billion by 2035 represents enormous potential for brands that position themselves as sustainability leaders. Early movers will capture premium market segments, build stronger consumer relationships, and establish competitive advantages that will compound over time.

At Vaaritex International, we understand the complexities of navigating sustainable textile sourcing. Our expertise in eco-friendly textile innovations, comprehensive certification knowledge, and global supply chain network positions us as your ideal partner in this sustainability journey.

Take Action: Partner with Vaaritex-intl Fabrics for Sustainable Excellence

Ready to transform your fabric sourcing strategy for 2026 and beyond? Vaaritex International Ltd. offers:

✅ Certified Sustainable Fabrics: GOTS, OEKO-TEX, and GRS certified materials across all categories

✅ Innovation Access: First access to emerging bio-based, recycled, and smart textile technologies

✅ Supply Chain Expertise: End-to-end traceability and transparency solutions

✅ Customization Capabilities: Tailored sustainable fabric solutions meeting your specific performance requirements

✅ Competitive Pricing: Strategic sourcing networks delivering sustainable materials at optimal costs

✅ Regulatory Support: Guidance on EU, North American, and global compliance requirements

Start Your Sustainable Transformation Today

📞 Contact Our Sustainability Experts:

- Email: support@vaaritex-intl.com

- Phone: +86-199-3490-9225

- Schedule a Consultation: Contact Us

🌐 Explore Our Sustainable Collection:

Visit vaaritex-intl Fabrics Products to browse our comprehensive sustainable textile range and request samples.

Frequently Asked Questions

Q: What’s the difference between GOTS and OEKO-TEX certification?

A: GOTS certifies organic fiber content and ethical production throughout the supply chain, while OEKO-TEX tests finished products for harmful substances regardless of fiber type. GOTS is comprehensive for organic textiles; OEKO-TEX ensures chemical safety across all materials.

Q: Are sustainable fabrics more expensive?

A: Initially yes, but total cost of ownership often favors sustainable materials through improved durability, regulatory compliance advantages, and growing consumer willingness to pay premium prices (up to 15-20% more for certified sustainable products).

Q: Can recycled polyester match virgin polyester performance?

A: Advanced recycling technologies are closing performance gaps. Enzymatic and chemical recycling produce recycled polyester virtually identical to virgin material, while mechanical recycling is ideal for applications where slight performance differences are acceptable.

Q: How do I verify sustainability claims from suppliers?

A: Request certification license numbers and verify them on official websites (global-standard.org for GOTS, oeko-tex.com for OEKO-TEX). Conduct supply chain audits and request third-party verification reports.

Q: What’s the minimum order quantity for sustainable fabrics?

A: MOQs vary by material and supplier. Vaaritex-intl Fabrics works with brands of all sizes, offering flexible ordering options from sampling quantities to bulk production runs.

References and Further Reading

Heuritech (2025). “Fabric Innovations 2026: The Future of Sustainable Textiles.” https://heuritech.com/articles/fashion-fabric-innovations/

ISPO (2024). “The Hottest Textile Trends for 2026 – Focus on Sustainability and Innovation.” https://www.ispo.com/en/awards/textrends/hottest-textile-trends-2026-focus-sustainability-and-innovation

Biancalani (2025). “Textile Trends Spring/Summer 2026: Where Innovation Meets Nature.” https://www.biancalani.com/news-and-events/textile-trends-spring-summer-2026-where-innovation-meets-nature

Research Nester (2025). “Sustainable Fabrics Market Trends, Size & Forecast to 2035.” https://www.researchnester.com/reports/sustainable-fabrics-market/6818

Global Organic Textile Standard. “GOTS Certification Standards.” https://global-standard.org/

OEKO-TEX Association. “OEKO-TEX Standard 100 Requirements.” https://www.oeko-tex.com/

Technavio (2024). “Sustainable Fabrics Market Growth Analysis – Size and Forecast 2025-2029.” https://www.technavio.com/report/sustainable-fabrics-market-analysis